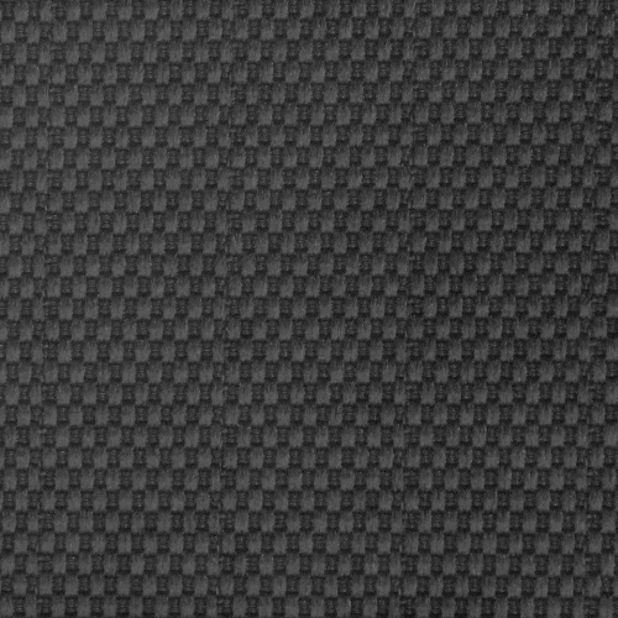

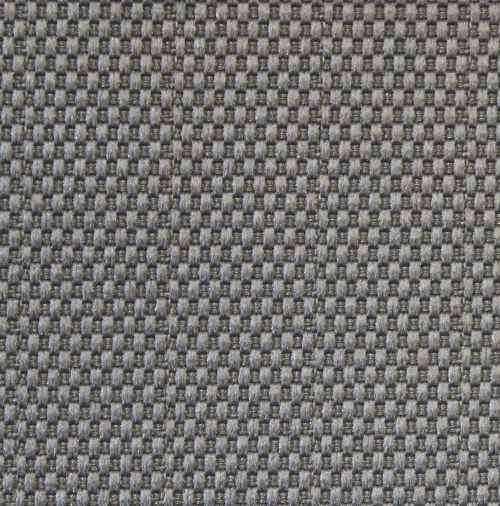

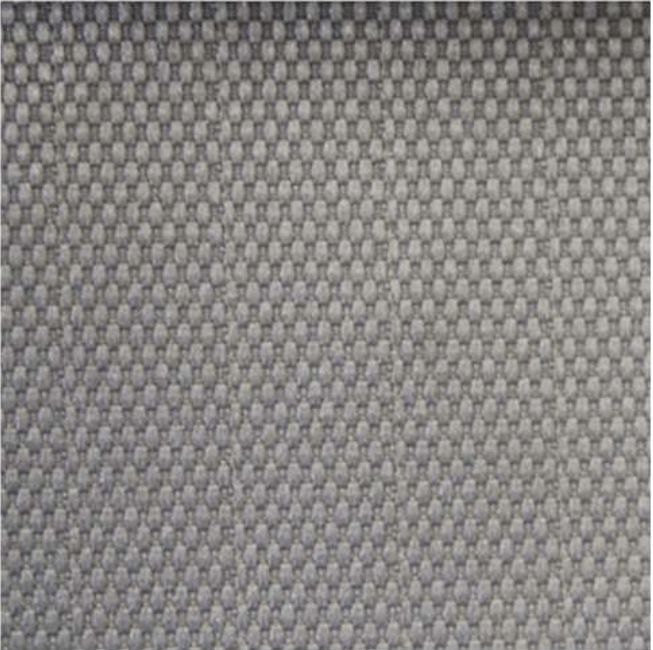

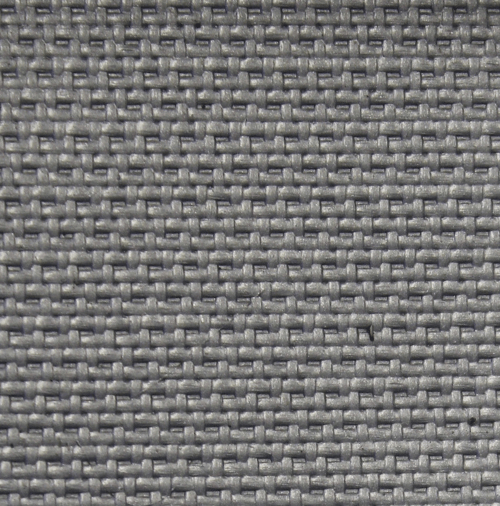

Materials

Everything we expect from quality materials: efficiency, durability and safety.

Our materials must meet very strict requirements for vehicle air ducts. They must be durable, resistant to abrasion, fire retardant, and stable across a wide range of temperatures. Their structure must not allow air through any areas other than the intended distribution holes. We only use materials that meet these criteria, many which have been designed specifically for air distribution.