Air Distribution

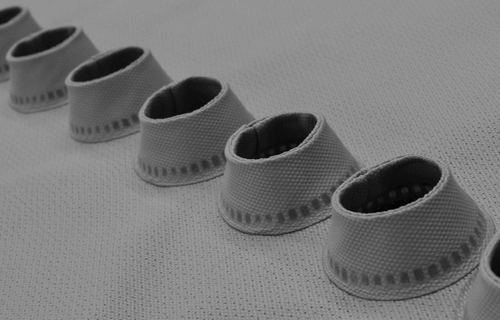

We have developed a better solution for the comfort of the passengers.

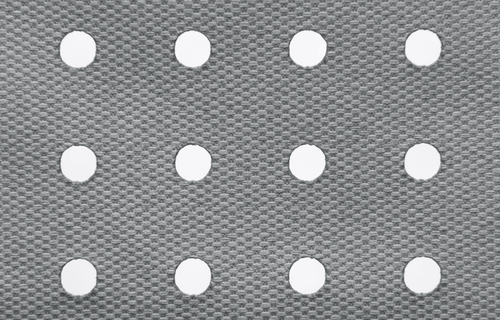

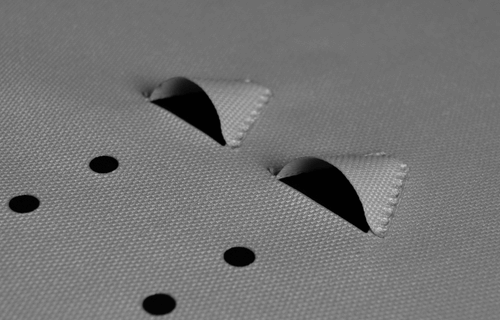

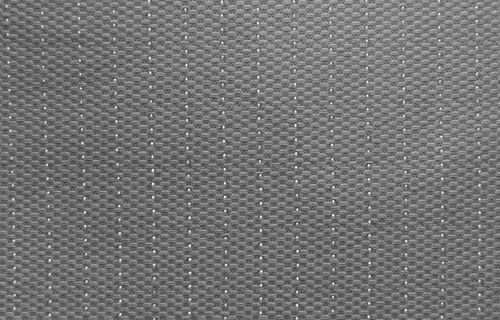

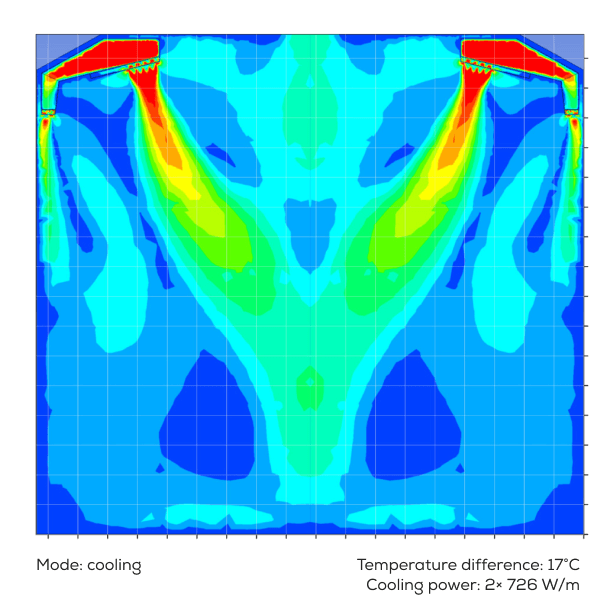

AirDIV is a fully-specialized supplier of air distribution systems for vehicles, ensuring an even distribution of air along the entire length of the vehicle. Our solution has been developed through countless laboratory tests, computer simulations and many years of experience. It offers a unique way to deal with the specific circumstances and limitations of the field.