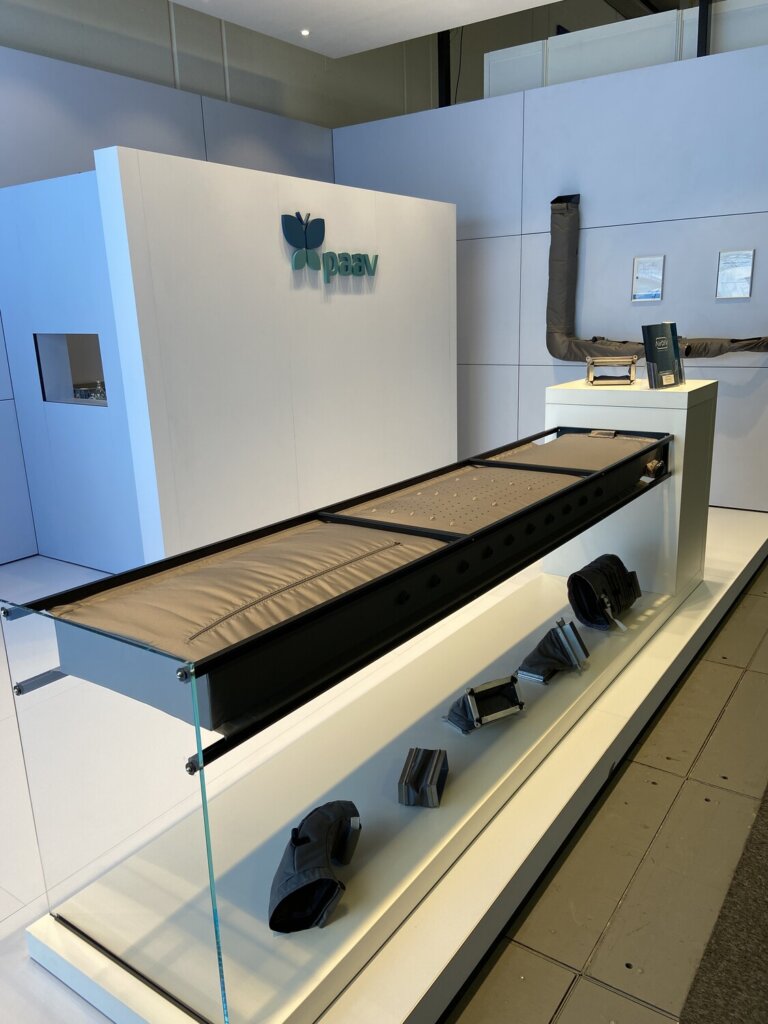

In the realm of railway HVAC systems, the materials used for air ducts are pivotal to ensure efficiency, safety, and comfort.

AirDIV, a leader in fabric air ducts for railway vehicles, presents AirDIV Poly 3 as a superior material choice for these systems.

This article delves into the features and benefits of AirDIV Poly 3, highlighting its fire resistance, low-weight antibacterial properties, strength, and versatility, making it ideal for applications where the best resistance to fire is required, such as metros, sleeping cars, and more.

AirDIV Poly 3 – EN45545-2 R1/HL3 material for rolling stock fabric air ducts @AirDIV

Exceptional Fire Resistance

One of the primary considerations for materials used in railway HVAC systems is fire safety.

AirDIV Poly 3 excels in this aspect, meeting the stringent fire resistance standards required for railway applications.

It is classified as HL 3 according to the EN 45545-2 standard for R1 material, ensuring it can withstand high levels of fire exposure and delay the spread of flames.

This high level of fire resistance is crucial for maintaining passenger safety in the event of a fire.

Low Weight for Enhanced Efficiency

AirDIV Poly 3 stands out for its low weight, a critical advantage in the railway industry where weight reduction directly translates to improved energy efficiency and reduced operational costs.

Weighing just 200 g/m², AirDIV Poly 3 is significantly lighter than traditional metal or composite ducting systems.

This lightweight nature facilitates easier handling and faster installation, leading to substantial savings in labor time and costs.

Moreover, the reduced weight contributes to lower fuel consumption and decreased wear and tear on the vehicles, enhancing overall operational efficiency.

Antibacterial Properties

AirDIV Poly 3 is treated to provide antibacterial properties, compliant with EN 20645.

This feature is particularly beneficial in railway environments where hygiene is paramount.

The antibacterial treatment helps prevent the growth of bacteria on the air ducts, contributing to a healthier environment for passengers and reducing the risk of infection spread, especially in high-traffic areas like metros, trams, and trains.

Robust Strength and Durability

Durability is a key requirement for materials used in the harsh conditions of railway systems.

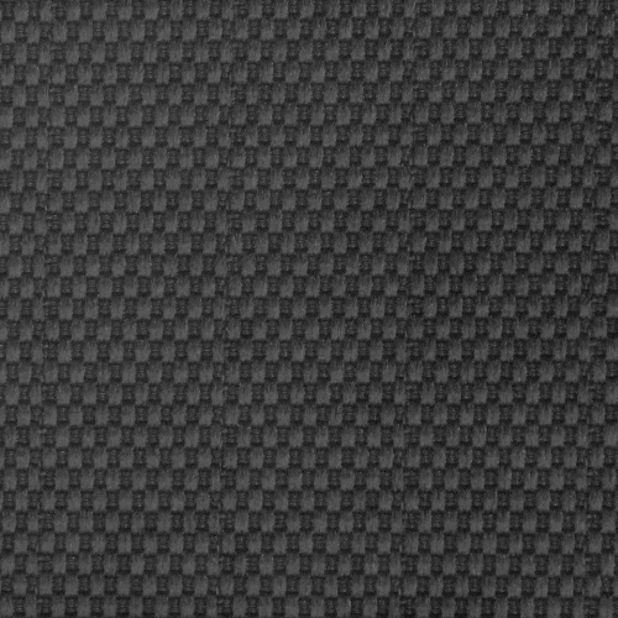

AirDIV Poly 3 is composed of 100% polyester multifilament fibers with inwrought carbonic fiber, enhancing its structural integrity.

The material boasts a warp/weft strength of 1800/1100 N (EN 13934-1), ensuring it can withstand the mechanical stresses and strains encountered during operation and maintenance.

Additionally, its impermeability and resistance to ozone and various cleaning agents make it highly durable under different environmental conditions.

Fabric air duct sample @AirDIV

Versatility in Applications

AirDIV Poly 3’s versatility extends beyond its mechanical properties and hygiene benefits.

Its ability to maintain functionality across a wide temperature range (-30 to +110°C) makes it suitable for various climatic conditions encountered in railway systems worldwide.

Moreover, the material’s antistatic properties further enhance its suitability for use in sensitive electronic environments often found in modern railway vehicles.

Ease of Maintenance

Maintenance of HVAC systems can be a complex and costly endeavor. However, AirDIV Poly 3 simplifies this process.

It can be cleaned effectively using conventional washing methods such as vacuum cleaning, cleaning with a wet cloth, or machine washing, making it easy to maintain without requiring specialized cleaning procedures.

The material’s impermeability also means that it can be disinfected using ozone, ensuring high standards of cleanliness are maintained.

Ideal for Critical Applications

Given its superior fire resistance, antibacterial properties, and robust durability, AirDIV Poly 3 is particularly well-suited for critical applications in railway vehicles.

This includes use in all rolling stock, where high passenger volumes necessitate stringent hygiene and safety standards. Its high fire resistance also makes it an ideal choice for areas requiring the highest safety standards.

Conclusion

AirDIV Poly 3 stands out as a superior material choice for railway HVAC air ducts due to its exceptional fire resistance, low weight, antibacterial properties, strength, and versatility.

These features ensure it meets the high demands of modern railway systems, providing a safe, hygienic, and durable solution for air distribution in various railway applications.

By choosing AirDIV Poly 3, railway operators can enhance the safety and comfort of their passengers while ensuring long-term reliability and ease of maintenance.

Download AirDIV Poly 3 material datasheet: https://airdiv.com/fabrics/#airdiv-poly3

Contact Us

For more information about AirDIV Poly 3 and how it can benefit your railway HVAC air duct systems, please contact us.

Our team of HVAC specialists and mechanical engineers is ready to assist you with tailored solutions to meet your specific needs. Reach out today to learn more about how AirDIV Poly 3 can enhance your railway vehicles.

)