Efficient and precise air distribution is a critical factor in railway HVAC (heating, ventilation, and air conditioning) systems, directly influencing passenger comfort, energy efficiency, and regulatory compliance.

Traditional metal ducting solutions present limitations in weight, flexibility, and uniform airflow distribution. Textile-based air ducts, designed with advanced computational modeling and tailored perforation technologies, offer an innovative approach to optimizing air management in railway vehicles, including metro systems, high-speed trains, regional trains, monorails, or trams.

This article explores the advantages of customizable textile ducting, considering airflow optimization, compliance with industry standards, and case studies demonstrating its effectiveness.

Fabric duct in railway car ©AirDIV

Advantages of Customizable Textile-Based Air Ducts

Precision Engineering for Optimized Air Distribution

One of the primary benefits of textile-based HVAC ducts in railway vehicles is their ability to be fully customized for specific applications. Unlike rigid metal ductwork, textile ducts allow engineers to tailor airflow parameters through advanced design tools.

Air distribution elements such as perforations and nozzles are configured using proprietary software to ensure uniform air supply, avoiding thermal stratification and air stagnation in passenger compartments.

Key benefits:

- Optimized perforation patterns ensure even airflow distribution, reducing localized discomfort.

- Perforation technology facilitates low-velocity air diffusion, preventing drafts and enhancing passenger comfort.

- Custom nozzle placement enables targeted airflow in high-occupancy zones, improving ventilation efficiency.

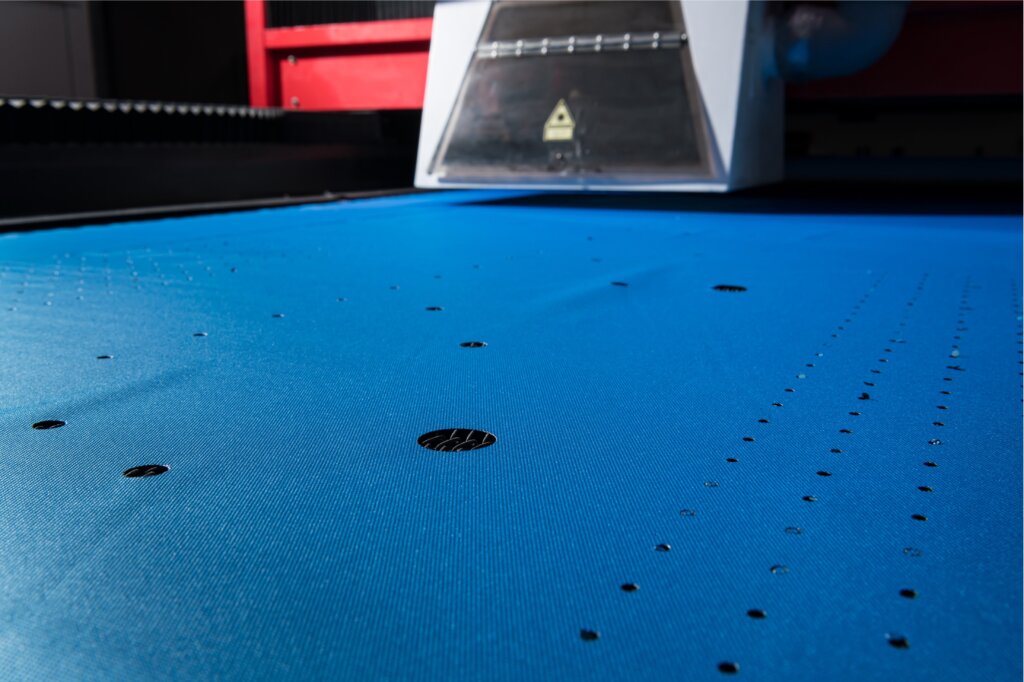

Laser perforation of fabric ©AirDIV

Compliance with Railway Safety and Performance Standards

Railway HVAC components must adhere to stringent safety and performance standards to ensure reliability and passenger protection. Textile air ducts are engineered to comply with EN 45545-2 (HL3 for R1 materials), the European fire safety standard for railway applications, which mandates strict flammability, smoke, and toxicity requirements.

An additional key standard is EN 13129. This standard defines HVAC performance requirements for railway passenger compartments, ensuring adequate ventilation, temperature control, and air distribution. Textile air ducts contribute to compliance by providing uniform air distribution, reducing temperature fluctuations, and ensuring optimal airflow in confined railway spaces.

These standards guarantee that textile ducts not only meet but exceed safety and operational requirements in railway environments.

Weight Reduction and Space Optimization

Railway operators prioritize weight savings to enhance fuel efficiency and reduce operational costs. Textile ducts offer a lightweight alternative to conventional rigid ductwork, contributing to lower overall vehicle weight without compromising structural integrity. Moreover, their flexible nature allows for easy integration into space-constrained areas within rolling stock, optimizing HVAC layout efficiency.

Comparative weight analysis:

| Component Type | Weight per Meter (kg) |

|---|---|

| Metal Ducting | 5.0 – 10.0 kg |

| Textile Ducting | 0.5 – 1.5 kg |

Noise and Vibration Reduction

Metallic air ducts can contribute to HVAC system noise due to airflow turbulence and structural vibration. Textile ducts, in contrast, possess sound-dampening properties, absorbing airflow noise, not conveying noise and reducing vibrations transmitted through the vehicle structure. This leads to a quieter cabin environment, enhancing the passenger experience and meeting stringent acoustic standards for modern railway transportation.

Air distribution from textile air duct ©AirDIV

Case Studies and Performance Validation

Implementation in Metro Systems

A case study conducted in a European metro system demonstrated that custom textile air ducts helped one major OEM reduce installation time by 90% compared to traditional rigid ducting. The OEM also saved 60% of human resources for ductwork mounting, leading to significant cost reductions. In addition, perfectly even air distribution was achieved in the metro cabin, contributing to high passenger comfort.

High-Speed Train Applications

A high-speed train operator implementing textile air ducts achieved a nice reduction in vehicle weight, leading to lower wear and tear on the train as well as decreased operational costs. Additionally, the project ensured the desired passenger comfort through uniform and quiet air distribution in passenger saloons, enhancing the overall travel experience.

Frequently Asked Questions (FAQ)

How do textile ducts compare in durability to metal ducting?

Modern textile materials used in HVAC applications undergo rigorous testing for mechanical wear, fire resistance, and environmental exposure. They are designed to withstand the operational lifespan of railway vehicles with minimal maintenance requirements.

Can textile ducts be integrated into existing railway HVAC systems?

Yes, textile air ducts are highly adaptable and can be retrofitted into existing HVAC systems without major structural modifications, making them a cost-effective solution for fleet upgrades.

Do textile air ducts affect air quality in passenger compartments?

On the contrary, textile ducts enhance air quality by preventing dust accumulation, allowing for easy cleaning, and supporting the integration of antimicrobial treatments to minimize bacterial growth.

Conclusion & Recommendations

Customizable textile-based air ducts offer a superior solution for railway HVAC systems, providing tailored airflow management, compliance with safety standards, and significant operational benefits. Their lightweight design, noise reduction properties, and energy efficiency make them an ideal choice for modern rolling stock, metro systems, and trams.

About AirDIV Group

AirDIV Group is a leading innovator in textile air distribution solutions for railway vehicles. With cutting-edge engineering and proprietary airflow optimization software, we deliver customized HVAC solutions that enhance comfort and efficiency in transportation sectors worldwide.

For expert consultation on HVAC solutions for railway vehicles, contact AirDIV today and discover the future of air distribution technology.

References

- European Standard EN 45545-2: Fire Protection on Railway Vehicles

- European Standard EN 13129: Railway applications – Air conditioning for mainline rolling stock

)